PRODUCTS

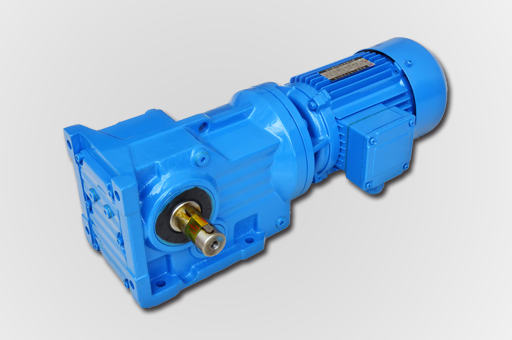

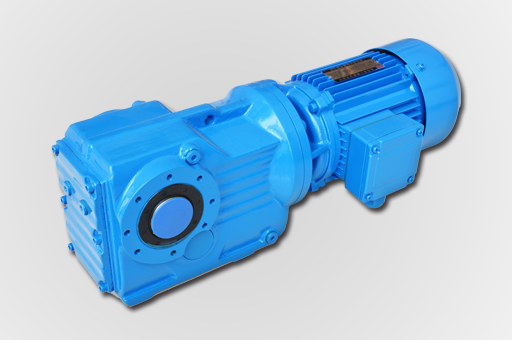

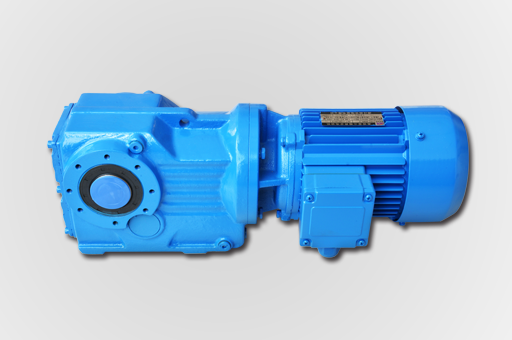

K Series Bevel Helical Gear Reducers

|

|

|

|

OUR ADNANTAGES

-High power density

-long service life

-high efficiency of the gear unit of over 90%

-Multi-stage gear units for low output speeds

We are manufacturing K Series bevel helical geared motors which offer ratios from 6:1 to 180:1 in three stages. Motors are available up to 90kW and output torque capacity up to 12,300 Nm.

The K Series Helical Bevel Geared Motor is designed with integral cast feet for base or end mounting and can be offered with single or double extended output shafts. Bevel Helical Geared Motor Units are also available shaft mounted or with output flanges and are available for mounting horizontally or vertically. The units can also be offered with a bolt on torque reaction bracket and all variants are available either motorized or with an input shaft assembly.

SPECIFICATION

| Housing material | HT200 high-strength cast iron for K37,47,57,67,77,87 |

| Housing material | HT250 High strength cast iron for K97,127,157,167,187 |

| Housing hardness | HBS90-240 |

| Gear material: | 20CrMnTi |

| Surface hardness of gear | HRC58°-62° |

| Gear core hardness | HRC33°-40° |

| Input/output shaft material | 40CrMnTi |

| Input/Output shaft hardness | HB220-250 |

| Heat treatment | tempering, cementing, quenching etc |

| Efficiency | 94%-96% |

| Noise(Max) | 60-68dB |

| Tem.rise: | 40°C |

| Tem.rise | 50°C |

| Vibration | ≤20um |

| Backlash | ≤20Arcmin |

| Motor | IP54, F class |

| Motor shaft | 40Cr, Tempering, cementing, quenching etc. |

KINGEAR Transmission will help you

● Providing suitable gearbox and combined gearbox to meet your application needs;

● Lowering maintenance cost and increasing operation efficiency;

● Improving production capacity and bringing economic benefits.